Made in HollandDesigned and manufactured in the Netherlands. Our most important pumps-series and installations are entirely "made in Holland". Here we are not talking about assembling components bought elsewhere or passing on products invented and developed by others. We investigate, invent, develop and produce ourselves. This includes the hydraulic and strength calculations in simulation software up to the physical tests of 3D-printed prototypes. |

"We develop, make and assemble the pumps and systems in our Dutch factory" |

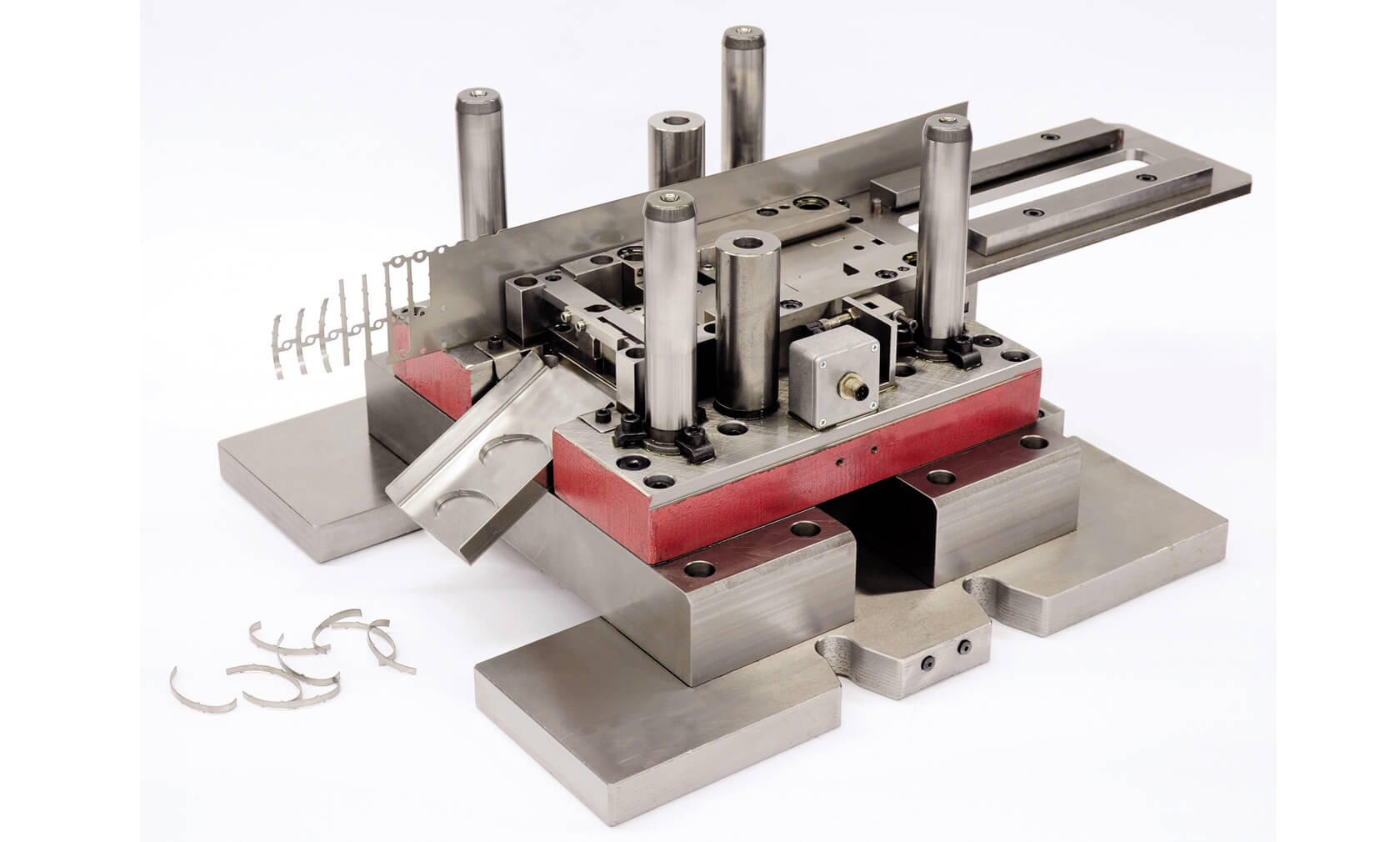

Efficient and guaranteed qualityTo guarantee high and stable quality, and to be able to compete against low-wage countries, our production is highly mechanised and robotised using laser welding, TIG welding, or projectile welding, abutment seaming, stamping, deep-drawing, turning, milling, etc.More than 25 "robots" produce as many different different pump parts as are required for the working inventory, ready to be deployed directly to the assembly line. |  |  |

| Fast, customised deliveryWe rarely hold ready-to-use pumps in stock. A sophisticated process makes it possible to assemble tens of thousands of different pump and installation variants directly for the customer. And it can be very fast, within 2 working days, or faster if required.Watch how our DPV pumps are made |

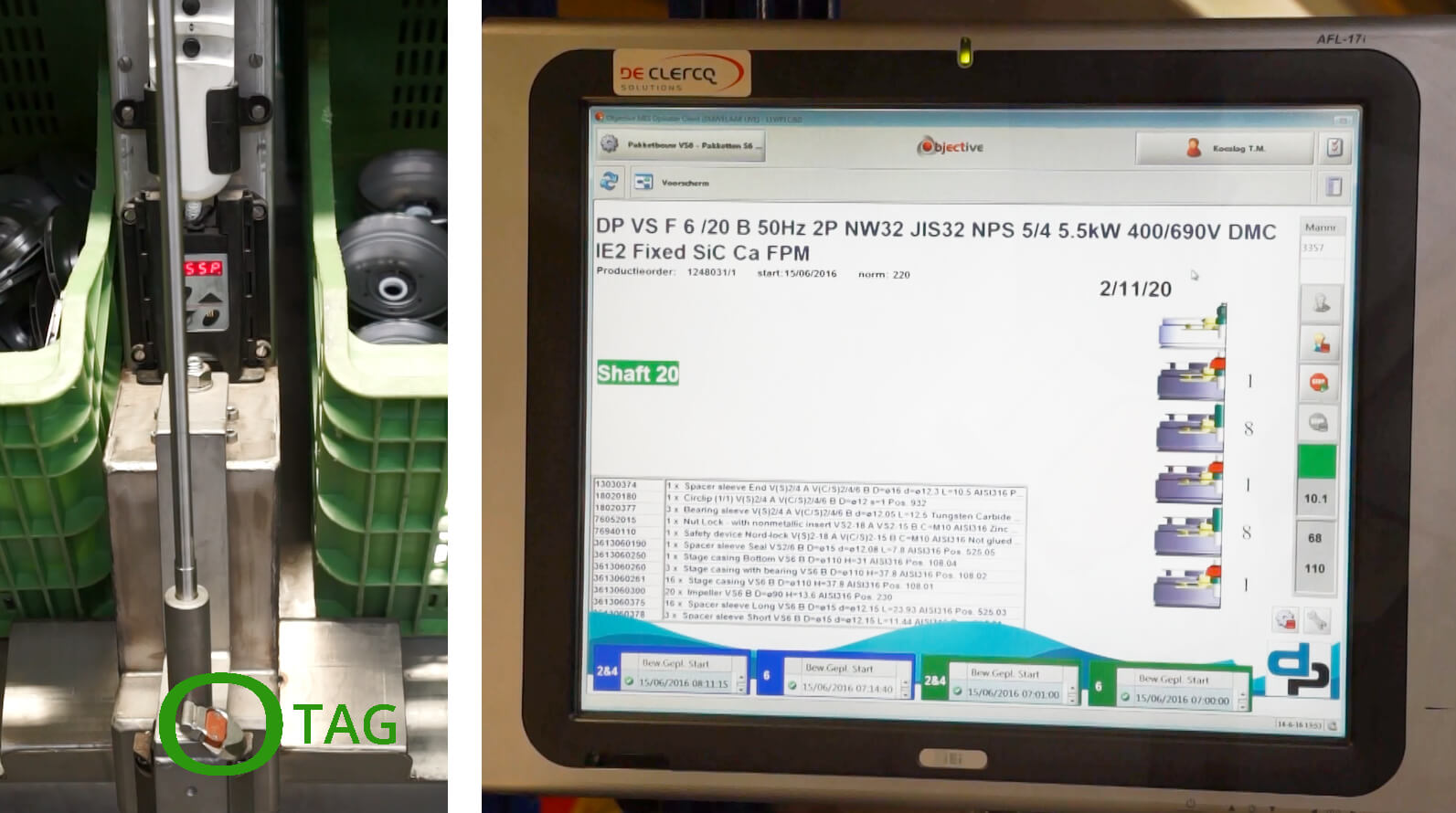

TraceabilityUsing our state-of-the-art warehouse & production management systems, we keep track of when each pump or system is produced, tested and shipped in real time. Step-by-step, the progress is scanned (each pump has a tag) and operators on the assembly lines can see exactly which components should be used.In addition, computer-controlled checks ensure this actually happens and whether, for example, the correct clearance and torques have been applied; which means there is virtually no chance of a pump being assembled incorrectly. |

|

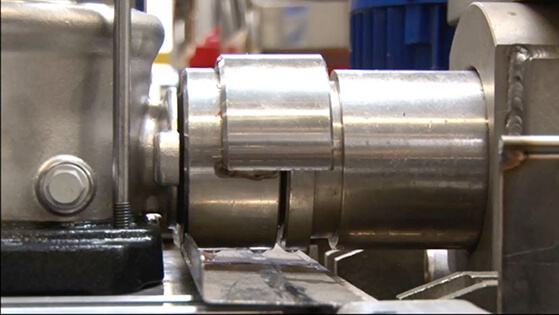

Testing & reportsOf course, all pumps we produce in Alphen aan den Rijn are thoroughly tested before being transported to our customers. For example, we measure if the build-up of pressure and volume corresponds with the given pump curves. Additionally, we check the sound and vibration levels. We also pressurise the pump to preclude leakages.We can retrieve this test report for every single pump that leaves the factory at a later time. For every pump and system, it shows how and when it was built. This means, if there is a problem when the pump is put into use, we can at least establish the "starting point". |   | Clean testing water guaranteedThe test water we use is monitored regularly and treated constantly. The water is changed daily, after which the ozone and UV treatments prevent it from getting contaminated. In fact, it is inevitable that a bit of water always stays behind after the test and we want to be sure that this is guaranteed to be clean and drinking-water safe at the moment the pump leaves our factory. |

Factory tourTake a few moments to view our production facility in Alphen aan den Rijn and discover where our pumps are used. |