The power of innovation

|

Working range

|

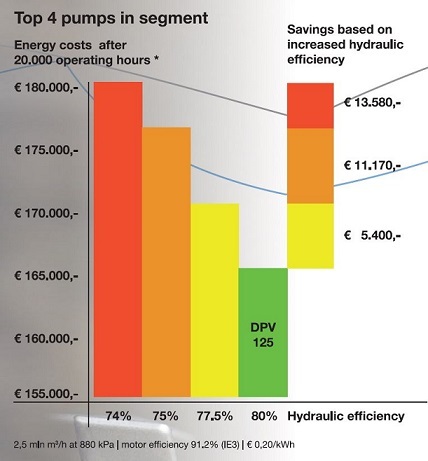

Advanced hydraulic design with Dutch rootsThe complete design of this pump series, as well as the tools used to make them, are designed and manufactured in the Netherlands. This results in a particularly energy-efficient design that achieves some of the highest scores in the market. The most recent addition to the DPV 125 product range even achieves the highest efficiency in its class.

Other advantages of designing a pump series in house are:

|

Download documentation

Contact our specialists |

Newest vertical centrifugal pump, DPV 125: highest efficiency in its class

Duijvelaar Pumps introduces the DPV 125. Our most advanced vertical multi-stage centrifugal pump for transporting large volumes of drinking and process water.

It is perfect for the increasing demand for a robust, compact and efficient pump with larger capacity (nominal capacity at maximum efficiency: 125 m3/h). Applications include, for example, water transportation, drinking water and fire-extinguishing systems, boiler feed, district heating, or cleaning and washing facilities.The DPI 125 is not only the most energy-efficient pump in the segment, but also flexible due its compact size, and durable due to its quality materials and construction techniques.

|

Low-NPSHr to prevent cavitationCavitation is caused by too low suction pressure, in relation to the internal resistance of the liquid in the pump and the vapor pressure of a liquid (the higher the temperature, the higher the vapor pressure). In case of cavitation, pump problems occur because of imploding 'bubbles' generating an intense shock wave. Life expectancy of the pump decreases because of deteriorating of the metal and extra wear on moving parts due to imbalance and decreased cooling and lubricating properties of the cavitating liquid. Without cavitation you are assured of a quiet and long-lasting smooth operating pump.DP has developed a specially designed low NPSHr impeller and bottom stage casing for the DPV & DPH(S)Ipump rage with significant lower NPSHr value. Due to this special low NPHSr design, the pump can be used in a wider range of applications to ensure high reliability and smooth operation of the pump even in case of low suction pressure and/or high temperature and vapor pressure of the liquid. Read more

|

Robust design that is safe for drinking water

|

3,000,000 possible variations

The DPV series

is a modular series of pumps that can be customised in countless numbers of

ways:

|

Wide number of applications

|

Applications

|

Reduction of servicing time and process halt

Reduction of servicing time and process halt