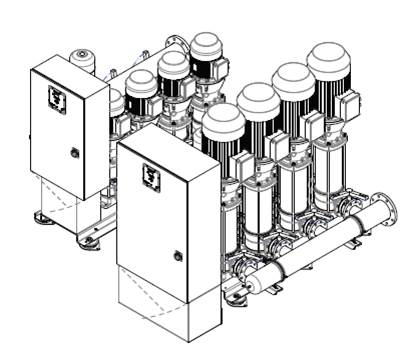

Hydro-Unit Utility Line

Hydro-Unit Base Line

Hydro-Unit Single and Base Line economy

Hydro-Unit Single Line

Hydro-Unit Premium Line

Versatile powerhouse

for demanding applications

|

Working range

|

Flexible assembly and delivery times

This series of

systems offers countless designs to meet the specifications of your project. Our broad

experience and direct lines to development and manufacturing departments offer

customisation, as well as unprecedented flexibility to adapt to extreme

challenges concerning the delivery or specification.

|

Download documentation

|

Compact and accessibleThe Utility Line pressure boosting systems deliver great performance, yet they are designed to be very compact; the system fits through an 80cm standard door with the pressure pipes dismantled; flexible installation and set-up remains possible in small spaces. Integrated check valves in the discharge bend save space and reduce the number of connections compared to separate check valves. Integrated check valves in the discharge bend save space and reduce the number of connections compared to separate check valves.

In addition, the location of the switch box is flexible, either in the technical room, or in a place of choice next to the system.This innovative design also makes the systems easily accessible for quick maintenance.

The Utility Line is controlled by the Megacontrol pump control unit, which was developed in house. This intelligent control system provides very accurate regulation, and the system can be integrated easily into a new or existing Building Management System.The control unit can have a read out via Modbus or profibus and provides: |

Exchange

while maintaining system pressure

|

Technical features Hydro-Unit Utility Line:

|

|